Cone crusher Indonesia is used for the secondary crushing. Cone crusher doe sale can crush the material with high hardness. It can be used various kinds of crushing production line. There are several types of cone crusher, single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, compound cone crusher, and Spring cone crusher. Here I will introduce the details and advantages of each type cone crusher machine, we have spring cone crusher, compound cone crusher, Symons cone crusher, multi-cylinder hydraulic cone crusher and single-cylinder cone crusher. Customers can choose the suitable type according the actual requirement.

Spring Cone Crusher

Spring cone crusher is one of the earliest cone crusher. It is an advanced crusher with high power, large crushing ratio and high productivity. When the spring cone crusher works, the motor drives the large circular bevel gear at the bottom of the eccentric sleeve through the hydraulic coupling and the small bevel gear, so that the eccentric sleeve rotates, causing the cone to swing and crush the material.

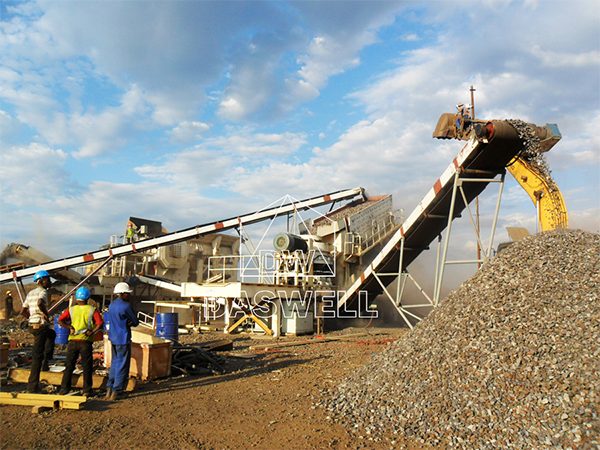

In addition, we also can supply the cone crushing plants. Cone crusher plant is a crushing production including cone crusher machine, equipped with other auxiliary equipment, it can crush the material. According to your requirement, it can be a mobile cone crusher plant, portable cone crusher, mobile cone crusher.

| Type | Dia. of Cone(mm) | Adjusting Range of Discharge Opening(mm) | Max Feed Size(mm) | Capacity(t/h) | Motor Power(kw) | Weight (t) | Overall Dimension(mm) |

| SCS-600 | 600 | 12-25 | 65 | 15-25 | 30 | 5.5 | 1740*1225*1940 |

| SCF-600 | 3-13 | 36 | 5-23 | 30 | 5.5 | 1740*1225*1940 | |

| SCS-900 | 900 | 15-50 | 115 | 50-90 | 55 | 10.18 | 1990*1640*2380 |

| SCM-900 | 5-20 | 60 | 20-65 | 55 | 10.19 | 1990*1640*2380 | |

| SCF-900 | 3-13 | 40 | 15-50 | 55 | 10.27 | 1990*1640*2380 | |

| SCS-1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 24.7 | 2805*2300*2980 |

| SCM-1200 | 8-26 | 100 | 50-150 | 110 | 25 | 2805*2300*2980 | |

| SCF-1200 | 3-15 | 50 | 18-105 | 110 | 25.6 | 2805*2300*2980 |

Compound Cone Crusher

The compound cone crusher adopt t he hydraulic cylinder and spring, transmission by belt, it has the function of hydraulic cavity cleaning. A hydro-cylinder for chamber clean can quickly remove aggregates and non-breakable material, to greatly shorten maintenance time. The lubricating system is provided with an oil return and temperature protection device, and interlocked with a main motor, so that the main motor is protected from damage.

| Model | Cavity Type | Stroke(mm) | Max. Feeding Size(mm) | Discharging Opening Adjusted Scope(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| CS1400C | Coarse | 30 | 235 | 30-60 | 210-530 | 220 | 25 |

| CS1400M | Medium Coarse | 30 | 215 | 25-50 | 200-500 | 220 | 25 |

| CS1200C | Coarse | 22 | 180 | 19-50 | 110-250 | 132 | 16 |

Symons Cone Crusher

Symons cone crusher is widely used in metallurgical industry, construction materials industry, road building industry, chemical industry and silicate industry. It is suitable for crushing ores and rocks with medium hardness and medium above.

Symons cone crusher has the features of strong crushing force, reliable structure, high working efficiency, and high capacity, low operation cost, easy adjustment. What’s more, the Symons cone crusher adopt compensating lubricating grease sealing, which can aviod lubrication oil being pollted by dust. So, that makes sure all the parts work reliable and have a long operation life.

Single-Cylinder Cone Crusher

Single-cylinder cone crusher this series cone crusher has bigger feeding size, it is suitable for various crushing plant for optimal performance, are widely used in medium and superfine crushing plant. Here I will introduce some features of the single-cylinder cone crusher.

- Wide application. It can crush hard rock, a variety of cavity types can be obtained by changing the liner plate of the same host machine, so as to adapt to various applications. The medium crushing type has a stable and large feeding port, which is used for the secondary crushing (even coarse crushing) of materials.

- Good Particle Shape. The optimized combination of crushing frequency and eccentricity and lamination crushing, so that the crushed material to maintain a better product grain shape.

- Lower production cost. The optimized liner design reduce the steel consumption per unit;

- Easy operation and maintenance. You just press the button control, the discharge port can be adjusted by liquid pressure, and can be carried out in the production process, so that the operation is more intuitive.

- High Automation Degree. Cone Crusher machine adopt the PLC control system. The operation and control is easy, reduce the labor cost.

Multi-Cylinder Hydraulic Cone Crusher

This type multi-cylinder hydraulic cone crusher adopt oil cylinder, so it is a kind of hydraulic cone crusher, which have the characteristics of semi-automatic cavity clearing function. Both Single-cylinder cone crusher and multi-cylinder hydraulic cone crusher has the function automatic over-iron protection, high automation degree.

Cone Crushers Working Principle

The movable cone do rotary pendulum motion under the driving effect of eccentric bushing, drive the crushing wall to extrude and roll the material between the mortar wall, material forced by multiple directions. According to materials their own grain crushing and grinding, eventually from stable stone particles. The materials meet the requirement will fall down from the rotation gap of the crushing wall, and the rest of material continue to be broken until meet the requirement.

Cone Crusher Price

Cone crusher machine is widely used in crushing industry. Many people pay attention to the price. Here i will introduce the factors effect the cone crusher price.

- Different cone crusher manufacturer means different company strength, product quality, after-sale service, etc. So you can’t only consider the price, but need consider comprehensive strength. Daswell provide high quality cone crusher with competitive price and considerable service.

- Different models mean different price. Among the influencing factors of the price of cone crusher products, the most important factor is the product specifications. The price of small size cone crusher and large model cone crusher machine is a big difference.

In a word, want to buy the suitable cone crusher, you need firstly know the functions and characteristics of the cone crusher you need, and then choose and compare the products.

Daily Inspection

Firstly, operator should check the external parts of the equipment, such as the valve plate, valve cover, valve seat of the crusher, and so on. These parts can be cleaned or repaired and replaced in time.

Secondly, check the safety valve, pressure regulator and air distribution device in detail to ensure the safe operation of the equipment in the production process and remove the threat to the personal safety.

Thirdly, carefully check the bearings of all parts of the crusher to ensure that the bearings are lubricated without damage. If any problems are found, maintenance measures should be taken immediately. Special attention is paid to the careful inspection and maintenance of some common and individual parts, in accordance with the operating procedures.

In this way, we can be responsible for the personal safety of users and operators, and the crushing equipment can also produce greater benefits.

Matters Need Attention

- During production operation, attention whether there is abnormal knocking sound inside; Whether the machine runs smoothly and the material enters and discharges smoothly; The operation of the oil pump, the oil flow indicator at each point, whether the oil temperature and oil pressure are normal;

- Check whether the following parts meet the requirements: the temperature of the oil discharged from the cooler is generally 45-53℃;Oil return temperature is less than 60℃; The pressure to the oil pipe is 0.08-0.15MPa;

- Check, adjust or replace the following parts: Check whether the fasteners are loose and tighten them if any;Check whether the lining plate is loose and worn. After the lining plate is worn to a certain extent, the discharging granularity becomes coarser, and it is necessary to improve the moving cone to adjust the width of the discharging port. If the lining plate is worn seriously, it is necessary to replace the lining plate of fixed cone or moving cone

Where to buy Cone Crusher?

Customers want to buy a high quality and good performance cone crusher equipment, firstly need find a professional and reliable cone crusher plant manufacturer. Daswell is professional in producing various kinds of crusher machines for over ten years, we have professional skill and mature technology for the cone crusher Indonesia manufacturing. We have set branch in Indonesia, so if you want to buy cone crusher or cone crusher plant in Indonesia, you can visit our warehouse there. And our salesman will help you choose the suitable type and model according to your situation and requirement. If you want get the details and price of our cone crusher crushing plant, you can leave an inquiry here and you will get reply within 24 hours.