Bolted silos are used to store large quantities of various kinds of bulk materials, such as cement, gravel, hardcore, fly ash and non-metallic mineral, etc. Bolted silo plays an important role in storage and engineering construction. We provide the different models: 50t, 70t, 80t, 100t, 150t, 200t, 300t, 400t, 500t, 800t, 1000t, 2000t, etc. Due to the transportation, we Daswell machinery mainly produce the bolted type cement silo. Here I will introduce the significance of bolted storage silo.

We not only provide bolted silos, but also provide turnkey solutions for the bulk materials storage and convey. Generally, there are two feeding methods: air blowing and bucket elevator. The conveying pipe of the bulk powder tank is connected with the feeing pipeline of the powder silo, use the gas pressure of the bulk powder truck to transport the powder in the tank to the powder silo. If the customer’s powder is packed in bags, the bucket elevator is generally used to load the powder, and then transported to the cement silo through a chute. Regardless of the feeding method, the powders enter the silo from the top of the silo.

| Capacity (t) | Diameter (mm) | Discharge Height (m) |

| 50 | 3260 | Customized |

| 70 | 3260 | |

| 80 | 3260 | |

| 100 | 3260 | |

| 150 | 3600 | |

| 200 | 4500 | |

| 300 | 5050 | |

| 400 | 5500 | |

| 500 | 6600 | |

| 800 | 8000 | |

| 1000 | 8000 | |

| 1500 | 10000 | |

| 2000 | 12000 |

Matters Need Attention When You Buy the Bolted Silo

- What material do you want to store?

- What’s the capacity of the bolted silo?

- What’s the unloading height required?

- Which feeding method is used to feed the silo.

- What equipment is connected with the outlet.

Advantages of Bolted Storage Silos

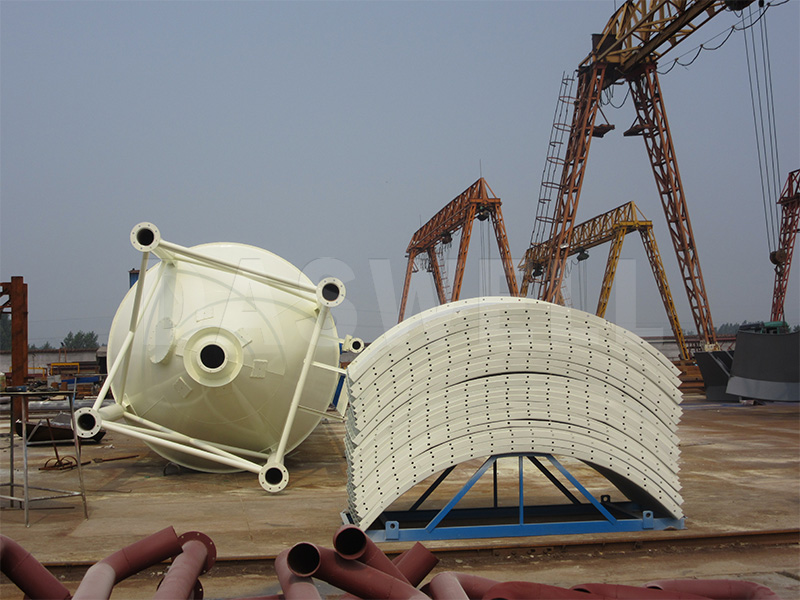

- The cement silo is made into sheets, the diameter of the silo body can be customized according to the needs, and it can be enlarged if there are special needs.

- Conventional cement silo body is generally cylindrical, the top and bottom of the silo are ball-shaped, and the base is round table barrel type, but in many cases, it is necessary to build other shapes according to the requirements of the site and the factory. In this case, the conventional cement silo can’t meet the requirements, and can make sheet cement silo.

- Bolted silo design can solve the problem of limited storage tonnage. After making it into a sheet shape, it can store 50 to 2000 tons, and it can also form a larger capacity storage group.

- The discharging system of the bolted type cement silos is advanced, and the energy consumption per ton of discharging is about 0.3-0.5 degrees, which greatly reduce the operation cost

- The bolted silos for cement has advanced technology and low maintenance costs.

- The service life of the bolted silos is longer. If it is properly maintained, it will not be a problem to use it for 50 years.

- After the cement silo is made into flakes, it can be used in a wider range. It can be widely used in the storage of cement and fly ash. What’s more, it can also store petroleum, chemical raw materials, etc.

- The transportation cost is greatly reduced, and it is easy to transport, it is a good thing for the purchaser.

- Convenient installation and dismantling.

- Strong sealing performance, and beautiful appearance.

| Capacity (t) | Diameter (mm) | Discharge Height (m) |

| 50 | 3260 | Customized |

| 70 | 3260 | |

| 80 | 3260 | |

| 100 | 3260 | |

| 150 | 3600 | |

| 200 | 4500 | |

| 300 | 5050 | |

| 400 | 5500 | |

| 500 | 6600 | |

| 800 | 8000 | |

| 1000 | 8000 | |

| 1500 | 10000 | |

| 2000 | 12000 |

F.A.Q.

Load 2 sets 100t bolted silo into a 40 HQ container.

We can provide both the silo and the accessories of the silo, such as dust collector, pressure safety valve, discharge valve, upper and lower level gauge, guardrail, feed pipe, etc. And we can also provide a complete package.

Yes, we have exported to many countries, such as America, Australia, Mexico, Brazil, Peru, Yemen, Philippines, Tanzania, Fiji, etc.

The installation of bolted silo is very easy, we will send you the installation video for your reference.

Our silo is equipped with an arch breaking device, which is composed of a flow aid air cushion and an air control box. The number of flow-aid air cushions is equipped according to the size of the bin.

Daswell Bolted Silo Supplier

Our Daswell machinery provides different bolted silo capacities, which are suitable for storing various bulk materials such as cement, fly ash, etc. The tank body is equipped with a material level system that can display the location of the material. The bolted steel silo deal with many problems such as the difficulty of exporting the cement silo, the difficulty of making cylinders on site, the difficulty of site transfer, and the ultra-wide transportation. Daswell machinery is one of the most reliable and professional bolted silo manufacturers in China, and we have set branch in Indonesia, if you have any demand for bolted silo, welcome contact Daswell tank supplier.